There is a major ongoing trend to develop multiple products in smaller batches, along with traditional high-volume drugs. This need for flexibility is changing the way suppliers design and manufacture assembly lines for medical devices.

Automation and modularity enable us to provide customers with tailor-made solutions, designed to meet any requirements and to deliver high-quality standards, even when scaling-up.

Automation is a cost-saving solution, but its main benefits result from the consistency of process it enables users to obtain: any unit produced is of identical quality. This makes it possible, among other things, to meet the highest regulatory requirements necessary to guarantee patients’ safety.

The benefits of modularity include increased production efficiency, cost savings, shorter lead times and openings for scalable capacity. A modular design also brings about greater flexibility to adjust to new devices, different device formats or market requirements.

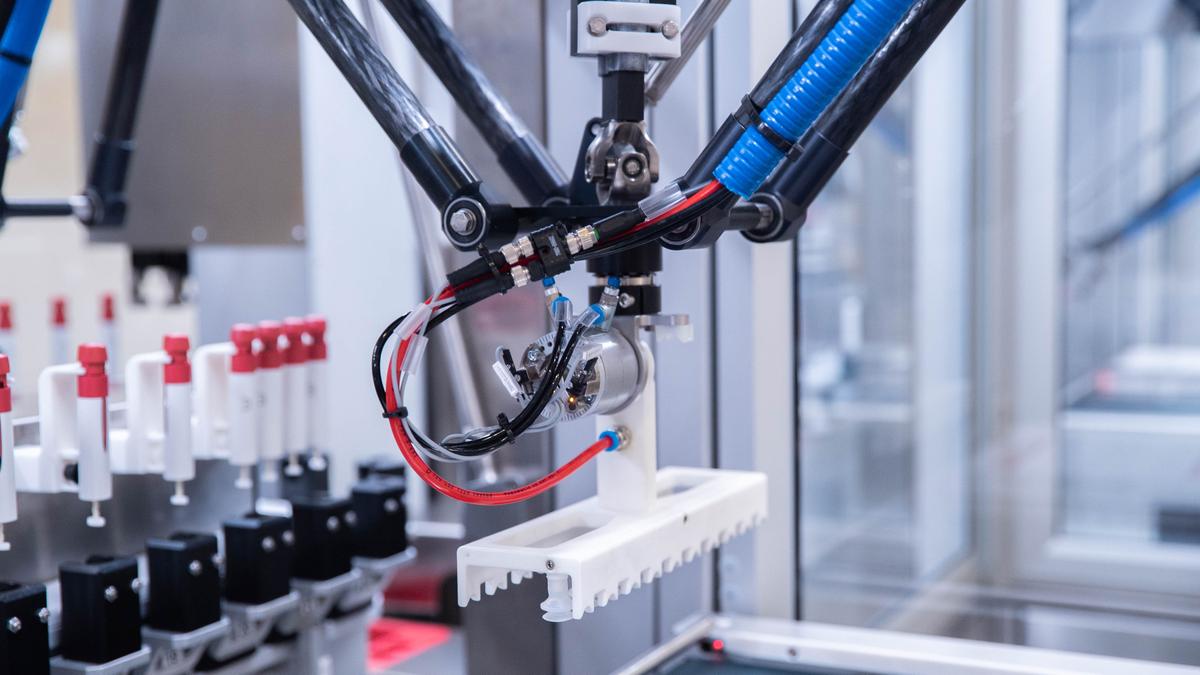

Leveraging on its expertise, SVM – the Group company specialized in assembly and packaging solutions - has designed BasiQX XTV, a modular assembly platform that reduces reliance on risky forecasts and also accommodates different formats and future capacity needs. With standardized technologies that have been tried and tested by customers, as well as scalable capacity and high automation levels, this platform is customizable to fit any device and guarantees the precise assembly of your particular product.

As part of an integrated approach to manufacturing, the platform embeds vision inspection controls for total inline quality. At each step, a camera or sensor checks that the task is performed properly. This includes, for instance, a positioning check for components, or – for pen injectors - individual priming to ensure the correct dosage.

One platform, countless applications. Learn more about our smart assembly system!