We offer state-of-the-art solutions for reliable particle inspection and detection of cosmetic defects, as well as complementary technologies, such as leak detection to test container integrity.

Whatever the task, we leverage our expertise and mastering of advanced technologies to synchronize the field of view, acquisition of images, illumination, container spinning speed, and rotation scheme.

With our particle tracking algorithm, we can efficiently detect particles in a wide range of liquid pharmaceutical products.

Very effective in minimizing spurious responses

Particle size and shape determined with robustness

High detection rate even through printing or occlusions

Very low false-rejects in difficult-to-inspect areas, such as the meniscus or bottom of the container

We have developed a patented method to reliably inspect even the most challenging suspensions or turbid products, such as insulin. Coupling high speed, line scan cameras and smart lighting systems we achieve a high detection rate and a simultaneous low false rejection rate.

Product homogenization

High-speed spinning to move particles outside

Side light projection to increase contrast

Line scan cameras for highest sensitivity and lowest noise

Multiple stations for correlating very dense suspensions

With common camera inspection techniques, it is hard to distinguish what is inside or outside the container when filled with very viscous products, such as hyaluronic acid.

Trajectory analysis to determine apparent speed

Reliable detection through printing or occlusions

Robust particle size and shape determination

Laser diffraction for denaturation detection

Freeze-dried products are typically difficult to inspect and their variable characteristics can easily be misclassified as defects.

Lighting and image capture techniques are the key to an accurate and precise automated inspection of lyophilized products.

Special lights to separate glass and particles from the variable lyo surface topology and appearance

Multiple lighting setups are used correlating the views to enhance the detection rate (DR) and lower false rejects

Multiple views enhance 360° detection of the lyophilized cake

Stevanato Group applies high-voltage leak detection (HVLD) for the detection of leaks in containers filled with liquid and head-space gas analysis (HGA) to test containers filled with lyophilized products.

Superior to Dye Testing

Objective

Fast > 600 pcs/min

HV is better than vacuum for viscous liquid

No influence on proteinaceous active products

Temperature-compensated conductivity for higher stability

HGA is applicable to packages optically transparent to NIR radiation in the range 760 -1400nm (tubular, molded, clear, amber glass, PP, PE, COC, COP).

Maintenance of headspace conditions created during package manufacturing

Sterility & stability for filled and finished packages

Robustness to variability: the model can systematically embed a much larger knowledge base in comparison to a rule-based classic solution

‣ This results in a reduction of false-rejects

Continuous improvement: the model can increase knowledge efficiently to improve the accuracy of the outcome

‣ This results in a further reduction of false-rejects

Furthermore, AI models can generalize the acquired information to classify several similar objects, and knowledge abstraction can be used to optimize costs. For example, different syringe flanges from various suppliers can be inspected using the same AI model.

Stevanato Group Vision AI, the platform integrating Deep Learning models, will enhance your equipment inspection performances, enabling you to reduce false rejects while increasing the detection rate.

Save money and rely on skilled AI and vision engineers.

Our main goal is to support our customers and help them successfully overcome their challenges. Sometimes this means adopting new and innovative methods of inspection. We have successfully tested the following techniques:

1. Near Infrared (NIR)

1. Near Infrared (NIR)

NIR is a spectroscopic method. A substance is illuminated with a broad-spectrum (many wavelengths or frequencies) of near infrared light, which can be absorbed, transmitted, reflected or scattered by the sample. Cameras typically identify particles embedded on the surface or the bottom of a lyophilized drug, NIR can be useful in spotting the contaminants lying inside the cake to distinguish the foreign particle (glass, paper, etc.) from the substance itself.

2. Bubble suppression

2. Bubble suppression

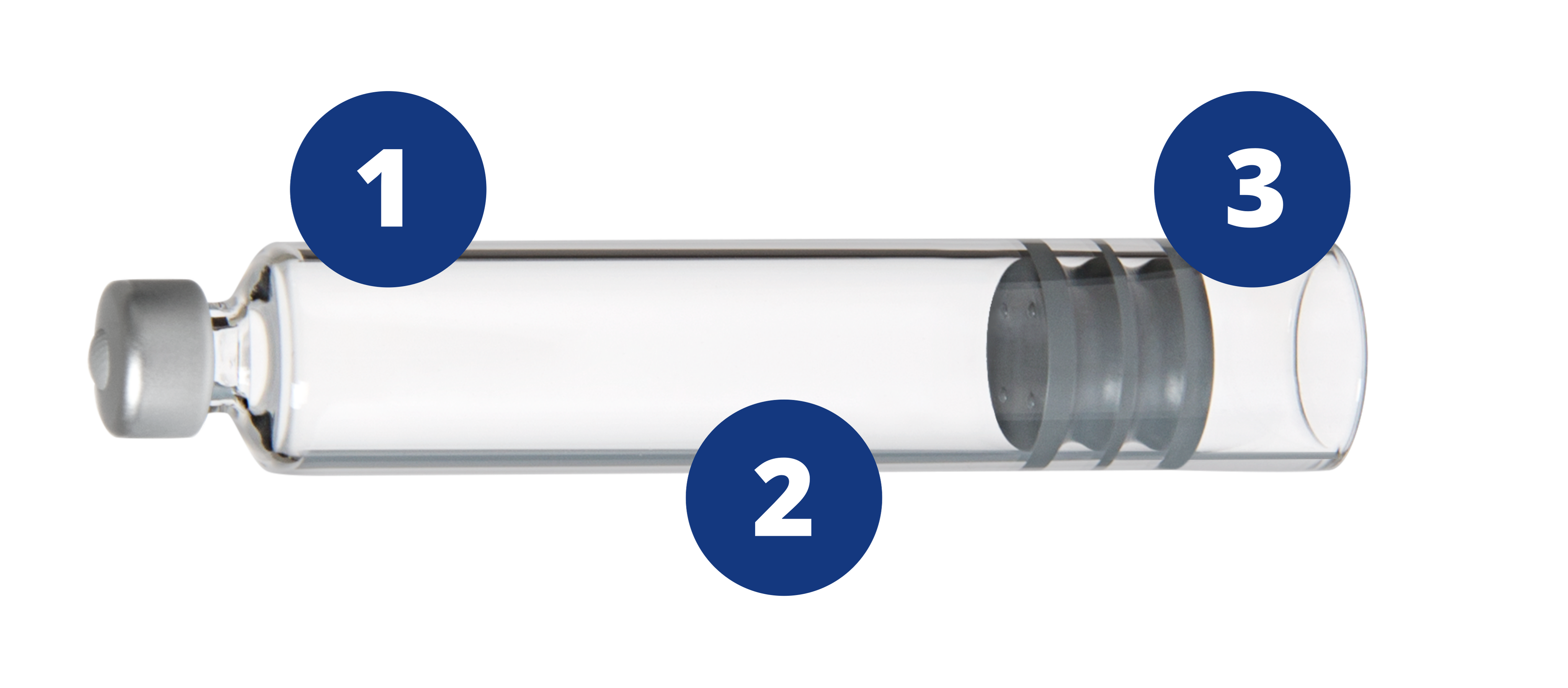

When inspecting parenterals, good products may be rejected as defective because cameras misclassify bubbles as particles. In several projects we have successfully implemented an efficient method to separate air bubbles from particles, which is particularly suitable for high-speed cartridge inspection. By spinning the container at high speed, we confine the bubbles at the center and look for defects in all the other areas.

3. X-Ray

3. X-Ray

The pharma industry still has reservations about adopting x-ray inspection as they fear product stability could be compromised by radiation. Recent studies show that pharma products are not affected in terms of their chemical makeup and efficacy following exposure to x-ray in inspection systems. This opens up new opportunities: X-ray could be used for the inspection of biologics or for automatic sampling of lyophilized products.